sheet metal parts design Do you know of anyone who wants longer lead times? Probably not. Always remember to let your manufacturer know what kind of hardware you want to use by including the details in your top level assembly information. Whether it’s a self-clinching nut like CLS-440-2, flush-head stud like FHS-M5-15, or . See more Before the incoming right-wing House of Representatives majority could elect a new Speaker, metal detectors were removed from the Capitol floor on January 3 2023 — but it is unclear who ordered it to happen.

0 · sheet metal pattern layout methods

1 · sheet metal part design guidelines

2 · sheet metal layout drawings

3 · sheet metal design rules pdf

4 · sheet metal design practice pdf

5 · sheet metal design calculations pdf

6 · how to fabricate sheet metal

7 · basics in sheet metal design

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

Do you know of anyone who wants longer lead times? Probably not. Always remember to let your manufacturer know what kind of hardware you want to use by including the details in your top level assembly information. Whether it’s a self-clinching nut like CLS-440-2, flush-head stud like FHS-M5-15, or . See moreGenerally, finishes serve two purposes. They can protect your part or they can make it look better. Some do both. Aesthetic . See moreImagine making hundreds of parts out of unfinished steel that are destined for installation in a salty, marine environment. Amazingly, we’ve seen quotes that request just that. Save . See moreSheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . The projection weld nut (spot weld nut) is widely used in the design of sheet metal parts. However, in many designs, the size of the pre-hole is not in accordance with the standard and cannot be accurately positioned. The . Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards. Whether you’re working with steel, aluminum, or copper, understanding the nuances of sheet metal processing .Our online sheet metal fabrication service can ship custom sheet metal parts and assemblies in as fast as 1 day. Request a quote today to get started. . We now offer automated design analysis for all sheet metal components, which .

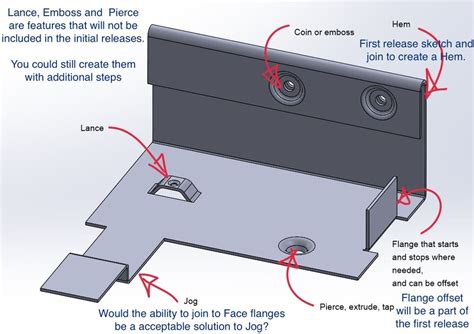

Specialized sheet metal design capabilities in Solid Edge deliver significant productivity gains compared to general-purpose CAD tools. Process-specific commands—like Lofted Flange for ducting, Part to Sheet Metal for hopper design, and Blank Body for press flat patterns—allow you to model sheet metal parts more quickly.Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Uploaded a design for 2 identical parts on Sunday evening, had the parts Thursday afternoon. The process was Incredibly easy and the prices are very reasonable. Good Grief . November 7, 2024.Protocase manufactures custom sheet metal parts, such as brackets, plates, frames, arms, bus bars, fixtures, and more, in 2-3 days, with absolutely no minimum order. . Protocase Designer is the fastest way to design parts, panels, and enclosures, featuring instant quoting and ordering. No prior experience required. The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

Why design sheet metal parts? Sheet metal designs are favored due to their versatility, cost-effectiveness, and durability. This process allows for the creation of a diverse range of products, catering to industries like automotive, aerospace, and consumer electronics. Sheet metal's ability to be easily cut, bent, and shaped, combined with its . How to Design Sheet Metal Parts for Fitting With Hardware 10/24/2024 Resources. Resources. Plastic Materials; Sheet Metals Materials; Surface Finishing; Frequently Asked Questions; Blog. View All. Selecting the Best Material for Your Sheet Metal Fabrication 5/6/2020 How Material Properties Impact Air Bending Precision and Tolerances .

Sheet-metal parts may have sharp corners, but designing a fillet of ½ the material’s thickness will make parts more cost-effective. Relief cuts help parts avoid “overhangs” and tearing at .Sheet metal fabrication is a great manufacturing process for creating long-lasting, durable, precise metal parts and enclosures. Because sheet metal parts are made from flat sheets of metal, different design considerations are necessary as opposed to CNC machining and additive manufacturing.In this article, we’ve outlined some of the top design tips and practices to help .As a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with the Lofted Bends . Tabs are often used in sheet metal design to align or join parts together. The width of a tab should be at least two times the thickness of the material for stability. The length of a tab should be designed to be as short as possible while still providing sufficient surface area for the intended connection.

Sheet metal parts design 2022-07-18 2022-07-18 Yan yifan Battery Bracket Holder, china sheet metal, . Quality inspection for sheet metal parts is crucial to ensure that the products meet specified standards and requirements. Here are.Sheet Metal Design: The Future of Sheet Metal Design. With its long history of engineering and craftsmanship, sheet metal design is poised for a bright future. This discipline, rooted in tradition but propelled by technological .Let's zoom in on one of the sheet metal parts and flatten it. . With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM .

Design Sheet Metal Parts with the Manufacturing Process in Mind. In order to successfully manufacture a product made of sheet metal, it is important to have a detailed and accurate design. This eBook provides all the . Choosing the right hardware and designing sheet metal to fit it is one of the most critical aspects of sheet metal manufacturing.Designing parts correctly for hardware can be difficult – countersinking material for flush rivets, picking the right depth of threading, ensuring the part is actually thick enough to accommodate screws. Sheet metal design.pptx - Download as a PDF or view online for free. Submit Search. . Spot welding and seam welding are two very popular methods used for sheet metal parts. Spot welding is primarily used for joining parts that normally upto 3 mm (0.125 in) thickness. Spot-weld diameters range from 3 mm to 12.5 mm (0.125 to 0.5 in) in diameter .

In the original design, the sheet metal required two separate bending processes. However, in the improved design, the sheet metal only needs one bending process to form the two sides at the same time. It is important to keep in mind that the more complex the bending process for the sheet metal, the higher the amount of material waste that may . Sheet Metal Overview. To fully understand the design intent of sheet metal components in the manufacturing industry, it is essential to study the types of sheet metal, their characteristics, and their components. Sheet metal is commonly defined as stock material between 0.006″ to 0.250″ in thickness. Dimensional tolerances are critical to ensuring that sheet metal parts fit together correctly and function as intended. They define the permissible limits of variation in a physical dimension which is a very crucial quality metric in sheet metal fabrication drawings. . brings over 15 years of experience to his role as a sheet metal design . It is the stage in the design and manufacturing process where all the sheet metal parts and components are joined together. A BIW structure of a passenger car typically consists of the following: High-pressure cast aluminum shock tower

cabinet lap steel youtube

Continuing in our series on Design for Manufacturing, this time we’re taking a look at sheet metal design.As the name implies, this involves designing components and assemblies using formed sheets of thin metal. Sheet metal is my favourite construction material as a designer, and I like to think of it as engineering origami. Welding is very beneficial to certain sheet metal enclosure and part designs. Here at Protocase, we’re able to weld light-gauge sheet metal using cold-metal transfer welding technology. But, as a general rule, deploying welding in your design will increase the cost. Bending operation. ( Design and manufacturing of sheet-metal parts C.-H. WANG and D. A. BOURNE 283 Fig. 2. Amada BMI00 bending system. bend lines. In this paper, all numbers associated with the sheet-metal parts in the figures are the indices of the corresponding bends instead of the actual bending sequences, unless specified explicitly.

I'm starting a new job pretty soon where I will be designing a lot more parts out of sheet metal. I was just wondering if there are any good reference books out there similar to the Black Book series, but for sheet metal design with all the most useful equations, tables of minimum bend radii, guides for relief cuts, etc.

sheet metal pattern layout methods

sheet metal part design guidelines

sheet metal layout drawings

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results.

sheet metal parts design|sheet metal design rules pdf